PRODUIT

DESCRIPTION

Débit extrême, force maximale, durabilité inégalée

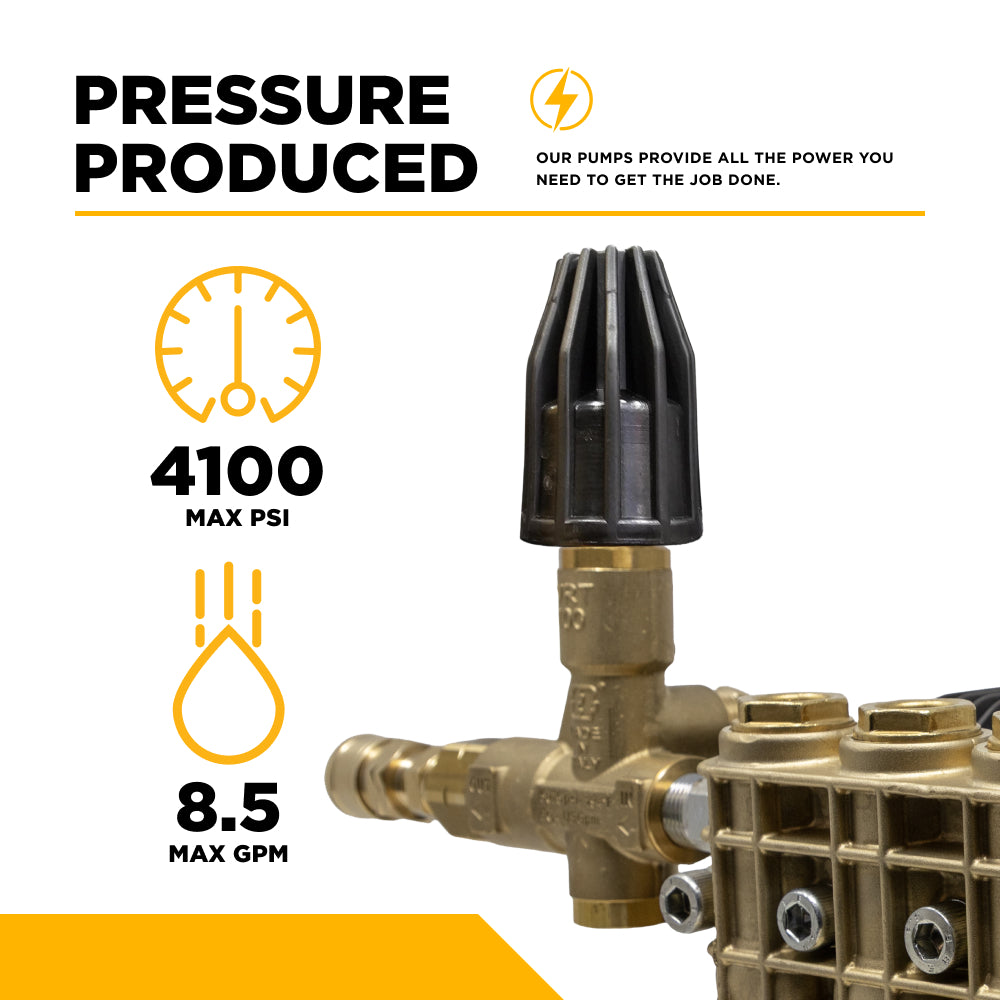

La pompe triplex à entraînement par courroie Centurion P10 (85.129.171B) est le fleuron de la gamme Centurion. Véritable concentré de puissance industrielle, elle délivre une pression de 4 100 PSI et un débit impressionnant de 8,5 GPM. Conçue pour résister aux conditions les plus extrêmes, elle est idéale pour une utilisation intensive et continue, même dans les environnements les plus difficiles. Les professionnels du nettoyage, de la maintenance industrielle et de l'agriculture l'apprécieront sans aucun doute.

Grâce à sa transmission par courroie performante, cette pompe est équipée de pistons en céramique triplex ultra-résistants et d'un collecteur en laiton, vous permettant ainsi de réaliser les travaux de nettoyage les plus exigeants avec précision et stabilité. Qu'elle soit couplée à un moteur à essence ou à un moteur électrique, cette pompe est le véritable cœur de tout système de nettoyage haute pression industriel ou commercial performant.

Caractéristiques principales

-

Modèle : Centurion P10 - CP CTB2S

-

Référence PMR : 85.129.171B

-

Pompe nue, référence : 85.120.171B

-

Fabricant de pompes : Centurion Pump

-

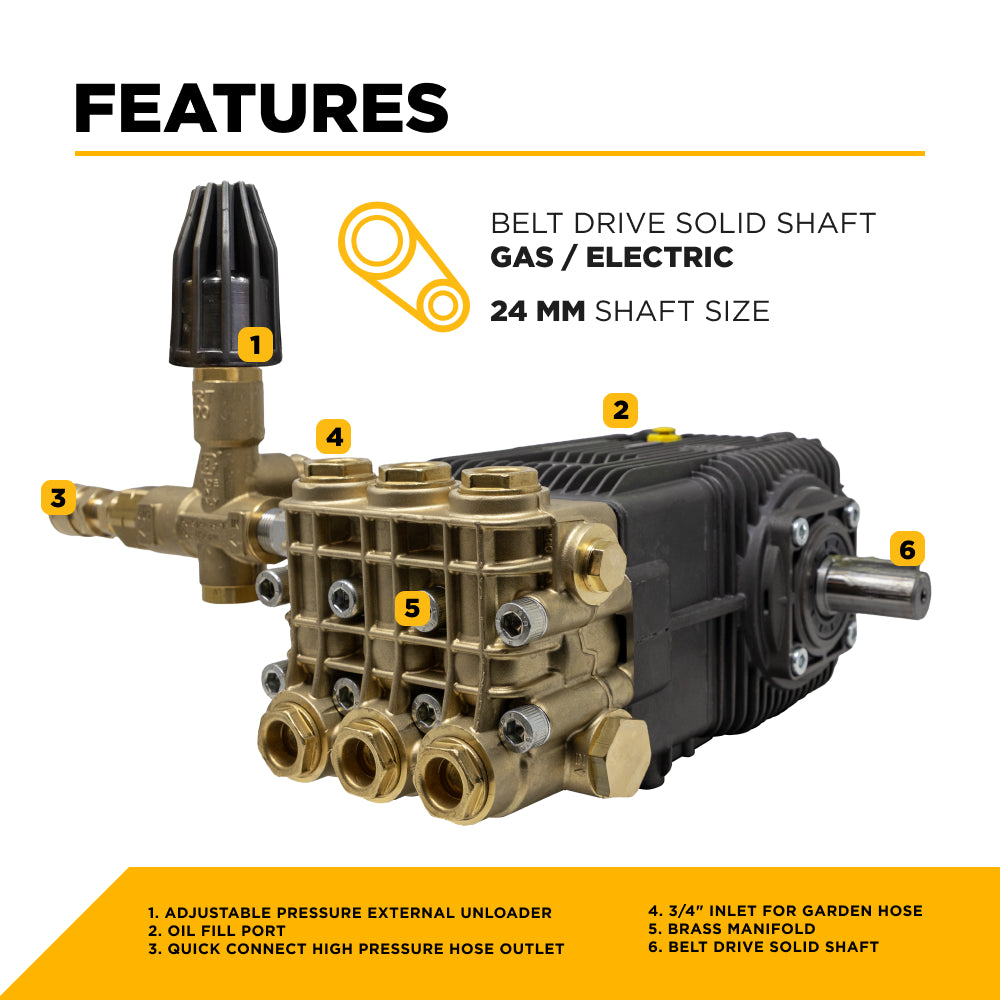

Type d'entraînement : Entraînement par courroie

-

Style de pompe : Triplex

-

Diamètre de la tige : 24 mm

-

Pression maximale : 4 100 PSI

-

Débit maximal : 8,5 GPM

-

Type de déchargeur : externe

-

Matériau du piston : Céramique

-

Taille de l'entrée : Raccord de tuyau d'arrosage 3/4" (GHF)

-

Diamètre de sortie : raccord rapide en laiton 3/8"

-

Injecteur de savon : réglable

-

Type de collecteur : Laiton

-

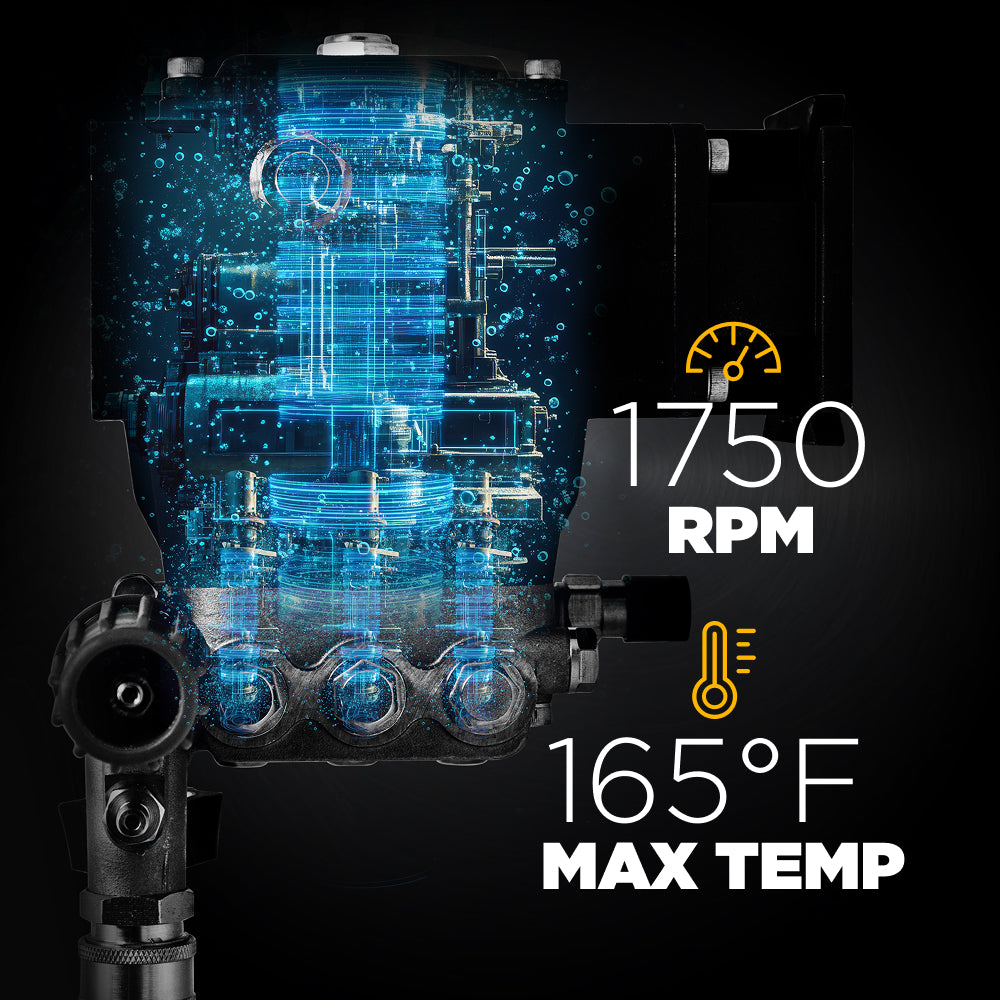

Vitesse de rotation de la pompe : 1 750 tr/min

-

Température d'entrée maximale : 74 °C / 165 °F

-

Soupape de décharge thermique : 85.300.022

-

Capacité d'huile : 1,1 L

-

Type d'huile : 30W sans détergent

-

Poids : 18 kg

-

Garantie : 7 ans

Conçu pour les travaux les plus difficiles

La Centurion P10 est conçue pour offrir des performances optimales et durables. Elle est pensée pour supporter les conditions d'utilisation les plus exigeantes, là où d'autres pompes lâcheraient. Que ce soit pour la construction, l'agriculture, la production industrielle ou l'entretien de flottes de véhicules, cette pompe est à la hauteur.

Avec un débit de 8,5 gallons par minute, vous pouvez couvrir rapidement de grandes surfaces, ce qui le rend idéal pour une utilisation avec des systèmes multi-pistolets et des nettoyeurs de surfaces. Et avec une pression de 4 100 PSI, préparez-vous à éliminer même les saletés les plus tenaces.

Le système de piston en céramique Triplex

Au cœur de la P10 se trouve le système de piston triplex de Centurion, véritable secret de son succès. Grâce à ses trois pistons en céramique rectifiés avec précision, cette pompe assure un débit d'eau régulier, constant et sans à-coups. C'est la marque d'une pompe conçue pour durer.

Pour les travaux intensifs, les pistons en céramique sont à privilégier car ils résistent à la chaleur et à la saleté lors d'une utilisation prolongée et intensive. Les pistons en acier, quant à eux, s'usent rapidement et ne peuvent rivaliser.

L'avantage de la transmission par courroie

Le système d'entraînement par courroie change tout. En reliant le moteur thermique à la pompe par une poulie et une courroie, on obtient un régime moteur plus bas, ce qui réduit les vibrations, la chaleur et l'entretien. De plus, grâce à l'amortissement assuré par la courroie, la durée de vie de votre pompe est considérablement prolongée.

Une puissance considérable pour des travaux de nettoyage exigeants

Le Centurion P10 offre un débit de 8,5 GPM à 4 100 PSI, un équilibre parfait entre débit et pression pour les travaux de nettoyage industriel les plus exigeants. Vous pourrez nettoyer plus rapidement et en profondeur, en toute simplicité, et ainsi réaliser des tâches qui seraient normalement un véritable défi.

À qui s'adresse cette pompe ?

-

Systèmes de nettoyage multi-armes

-

Nettoyeurs de surfaces jusqu'à 30 pouces\

-

Lavage de flottes et de camions\

-

Nettoyage de machines et d'équipements lourds\

-

Opérations agricoles, de construction et minières* Ateliers de production, quais de chargement et autres grandes installations

Rinçage plus rapide et productivité accrue : le volume d’eau impressionnant du P10 est un véritable atout. Un avantage crucial pour les entreprises et les équipes industrielles soucieuses d’optimiser leur temps.

Collecteur en laiton : conçu pour résister à la pression

Le collecteur en laiton du P10 est conçu pour résister aux hautes pressions et aux hautes températures sans se déformer ni se corroder. Sa robustesse mécanique et sa stabilité thermique supérieures lui permettent de maintenir des performances optimales, même en fonctionnement continu.

Il existe une différence majeure entre les collecteurs en laiton et ceux en composite ou en aluminium. Le laiton, contrairement à certains autres matériaux, ne se déforme pas avec le temps. Cela se traduit par moins de fuites et un débit plus stable tout au long de la durée de vie de la pompe. Les orifices en laiton usinés avec précision s'ajustent parfaitement aux raccords d'entrée et de sortie, réduisant ainsi les contraintes et simplifiant considérablement l'installation.

Déchargeur externe réglable

Le régulateur de pression externe du P10 vous offre un contrôle total sur la pression de votre système. Vous pouvez l'ajuster en fonction de chaque opération de nettoyage, qu'il s'agisse de décaper de la peinture sur du métal ou de rincer des surfaces délicates. La flexibilité est au cœur de sa conception.

Le dispositif de décharge fonctionne en renvoyant l'excédent d'eau vers l'entrée, vous évitant ainsi les pics de pression dommageables. De plus, étant externe, il est facilement accessible pour être ajusté ou remplacé au besoin, un atout considérable dans les environnements exigeants où chaque minute compte.

Injecteur chimique réglable

L'injecteur de savon réglable du P10 permet un dosage précis du détergent ou du produit chimique utilisé, pour un nettoyage optimal et une réduction maximale du gaspillage. Que vous utilisiez des dégraissants, des désinfectants ou des nettoyants moussants, vous pouvez ajuster le mélange selon vos besoins.

Ce système est conçu pour être durable et résistant à la corrosion, et il est conçu pour continuer à aspirer même à basse pression, vous pouvez donc compter sur lui pour fonctionner tout au long de sa durée de vie.

Soupape de décharge thermique pour la protection contre la surchauffe

Lorsque la pompe fonctionne en mode bypass (avec la gâchette de pulvérisation relâchée), l'eau peut devenir très chaude à l'intérieur. C'est pourquoi la P10 est équipée d'une soupape de décharge thermique (85.300.022) qui s'active pour évacuer l'eau chaude et faire entrer de l'eau plus froide. Ceci permet de maintenir une température de fonctionnement sûre et d'éviter la surchauffe qui pourrait endommager les joints, les pistons et les soupapes.

Cette caractéristique vous permet de faire fonctionner la pompe dans des environnements chauds ou de la laisser inactive pendant des heures sans craindre de l'endommager.

Faible régime moteur, rendement élevé

Le P10 tourne à 1 750 tr/min – ce n’est pas extrêmement rapide, mais il remplit parfaitement sa fonction en sollicitant beaucoup moins ses composants internes. Cette vitesse plus lente signifie :

-

Moins de vibrations et de bruit

-

Températures de fonctionnement plus basses

-

Durée de vie prolongée des joints et des roulements

-

Pression de sortie plus douce et plus stable

Ce faible régime moteur rend également le P10 extrêmement polyvalent : il est compatible avec les moteurs à essence et les moteurs électriques, ce qui vous permet de l'utiliser dans toutes sortes de systèmes commerciaux et industriels.

Lubrification et refroidissement de précision

Le carter du P10 a une capacité d'huile de 1,1 litre (37 fl oz), assurant ainsi une lubrification optimale des pièces mobiles, même sous forte charge. L'huile 30W sans détergent contribue significativement à réduire l'usure et les frottements.

Le vilebrequin forgé, les coussinets surdimensionnés et les bielles traitées thermiquement sont conçus avec précision pour fonctionner en parfaite harmonie sous fortes charges. Les contrôles et vidanges d'huile réguliers sont simplifiés, garantissant ainsi une durée de vie optimale de votre pompe pendant des milliers d'heures.

Conçu pour une utilisation commerciale intensive

Le P10 est conçu pour exceller dans les environnements les plus extrêmes. Sa puissance, son débit et son endurance en font un choix idéal pour :

-

Aires de lavage commerciales et industrielles

-

Lavage et entretien de la flotte

-

équipements agricoles et de transformation alimentaire

-

Nettoyage de machines lourdes et de chantiers

-

Préparation et restauration des surfaces

-

Systèmes de nettoyage multi-armes

Avec sa transmission par courroie à bas régime, sa conception triplex à grand volume et son collecteur en laiton robuste, le P10 peut continuer à fonctionner changement après changement dans des conditions exigeantes, offrant des performances sur lesquelles vous pouvez compter.

Maintenance et entretien faciles

Nous concevons nos pompes pour qu'elles soient aussi faciles à réparer que possible, afin que vous puissiez reprendre le travail rapidement. La configuration de la P10 vous permet d'accéder à tous les composants clés en quelques secondes : joints, soupapes, pistons et carter sont tous faciles à voir et à entretenir.

Le dispositif de décharge externe et l'orifice de remplissage d'huile facilitent grandement l'entretien, et les composants de la pompe sont conçus pour durer : vous n'aurez que peu d'entretien à effectuer au fil des ans. En cas de besoin de révision, les kits Centurion sont largement disponibles et très faciles à installer.

Ingénierie de précision de Centurion Pump

Chaque pompe Centurion est fabriquée à la main avec une grande précision, un contrôle qualité rigoureux et des matériaux haut de gamme. La P10 ne fait pas exception : elle est conçue pour offrir les meilleures performances de sa catégorie.

De ses pistons en céramique et de son collecteur en laiton à ses roulements haute performance et à son vilebrequin traité thermiquement, chaque composant est conçu pour être robuste, durable et équilibré.

Chaque pompe est testée en usine pour ses performances, son étanchéité et la précision de son débit ; ainsi, lorsque vous installez une Centurion, vous avez la certitude d'obtenir ce qu'il y a de mieux.

Pourquoi choisir le Centurion P10 ?

La P10 n'est pas une simple pompe haute pression, c'est un concentré de puissance de pointe conçu par des professionnels pour des professionnels qui n'attendent rien de moins que des performances optimales.

Principaux avantages :

-

Débit et pression à la hauteur : 8,5 GPM à une pression impressionnante de 4 100 PSI pour un nettoyage rapide et en profondeur.

-

Vous savez, ce système d'entraînement par courroie est plutôt ingénieux : moins de chaleur, une durée de vie plus longue pour les composants, ce qui est une bonne chose.

-

Ces pistons en céramique triplex sont tout simplement les meilleurs : ils résistent à la chaleur et continuent de fonctionner sans problème.

-

Un dispositif de décharge externe est bien pratique : la facilité de réglage de la pression et la sécurité d’utilisation sont un atout majeur.

-

Contrôler l'utilisation des produits chimiques devient un jeu d'enfant avec cet injecteur de savon réglable : ni dégâts, ni tracas, ni soucis.

-

Un faible régime moteur (on parle de 1 750 tr/min) signifie des performances d'une douceur incomparable et une usure bien moindre : exactement ce que vous recherchez.

-

Le collecteur en laiton est conçu pour durer : robustesse, stabilité et, surtout, il ne se corrode pas : c'est la solution idéale.

-

Supporte l'eau chaude ? Un jeu d'enfant. Jusqu'à 74 °C à l'entrée : Besoin d'eau chaude ? Aucun souci.

-

Nous garantissons notre travail pendant 7 ans : qualité, fiabilité – vous pouvez compter sur nous.

La pompe de nettoyeur haute pression Centurion P10 à entraînement par courroie triplex 4100 PSI 8,5 GPM (85.129.171B) offre une performance, une efficacité et une fiabilité réelles pour toute opération de nettoyage industriel ou commercial qui en a besoin.

Avec ses pistons en céramique, son collecteur en laiton et sa transmission par courroie à bas régime, la P10 allie puissance et longévité exceptionnelles. Elle établit de nouvelles normes en matière de débit avec un débit de 8,5 GPM et une pression de 4 100 PSI. Elle est également équipée de fonctionnalités telles qu'un déchargeur, un injecteur de savon et une soupape de décharge thermique, vous permettant ainsi de travailler en toute sécurité pour votre exploitation.

Conçue pour les travaux les plus difficiles et bénéficiant d'une garantie de 7 ans, la Centurion P10 est l'expression ultime d'une ingénierie de pointe - une pompe qui fonctionnera jour après jour pendant des années.

Centurion P10 - Conçu pour les pros qui savent qu'ils ne méritent que le meilleur.

Questions fréquentes sur les nettoyeurs haute pression

Comment ranger un nettoyeur haute pression ?

Pour garantir la durabilité de votre nettoyeur haute pression haute performance :

- Vidangez le réservoir d'essence pour éviter que le carburant ne se dégrade ou n'encrasse le moteur.

- Vidangez la pompe et les tuyaux de toute eau restante.

- Effectuer l'entretien nécessaire avant le stockage.

- À conserver dans un endroit sec.

- Couverture.

Qu'est-ce qu'un nettoyeur haute pression ?

Un nettoyeur haute pression est une machine de nettoyage qui utilise un moteur à essence pour alimenter une pompe à eau haute pression et une buse. Il sert à nettoyer les allées, les terrasses, les véhicules, le mobilier de jardin et bien plus encore en projetant de l'eau à haute pression afin d'éliminer la saleté, la crasse, les moisissures et autres débris. De nombreux modèles sont également équipés d'un réservoir de détergent pour une efficacité de nettoyage accrue.

Comment fonctionne un nettoyeur haute pression ?

Un nettoyeur haute pression fonctionne en aspirant l'eau d'un tuyau et en la propulsant à travers une buse haute pression. Le moteur à essence actionne la pompe qui pressurise l'eau, puis l'expulse à grande vitesse par la buse pour nettoyer la surface. La pression de l'eau est mesurée en PSI (livres par pouce carré) et le débit en GPM (gallons par minute). De nombreux modèles proposent également des réglages de pression d'eau ajustables pour s'adapter à différents besoins de nettoyage. BE simplifie le nettoyage haute pression grâce à des modèles disponibles pour les petits travaux comme pour les projets de nettoyage professionnels intensifs.

Nettoyeurs haute pression à essence ou électriques ?

La principale différence réside dans le fait qu'un nettoyeur haute pression à essence, réputé pour son pouvoir de nettoyage, est alimenté par un moteur à essence, ce qui le rend plus puissant et portable, tandis qu'un nettoyeur haute pression électrique est alimenté par l'électricité et est généralement plus silencieux et plus léger.

Les nettoyeurs haute pression à essence sont destinés aux travaux intensifs et aux grandes surfaces en raison de leur robustesse, tandis que les nettoyeurs haute pression électriques sont conçus pour les petits travaux.

Votre nettoyeur haute pression électrique BE est idéal pour les petits travaux et conçu pour être facilement transportable. Nous proposons une large gamme de modèles électriques. Nos modèles électriques sont fournis avec une longue rallonge pour une utilisation partout autour de votre maison.

Quels sont les éléments à prendre en compte ?

Lors du choix d'un nettoyeur haute pression à essence, tenez compte des éléments suivants :

- Pression (PSI) : Une pression plus élevée signifie une plus grande puissance de nettoyage, mais aussi un risque accru d’endommager les surfaces délicates.

- Débit (GPM) : Un débit plus élevé (GPM) signifie un nettoyage plus rapide car une plus grande quantité d’eau est distribuée.

- Puissance du moteur : Des moteurs plus gros signifient une durabilité et une puissance accrues.

- Portabilité : Poids, conception de la poignée et taille des roues pour faciliter le déplacement.

- Buses : Plusieurs buses de pulvérisation pour ajuster le jet en fonction des différentes tâches.

- Buse réglable : Permet d'ajuster avec précision l'intensité et le jet de pulvérisation en fonction des différents besoins de nettoyage.

Quelle pression dois-je appliquer ?

La pression requise (PSI) et la puissance de nettoyage dépendent de la surface à nettoyer :

- Usage léger (lavage de voiture, mobilier de jardin) : 1 300 à 1 800 PSI.

- Usage moyen (patios, clôtures, terrasses) : 2 000 à 3 000 PSI.

- Usage intensif (allées, murs de briques, gros équipements) : 3 000+ PSI.

De nombreux nettoyeurs haute pression sont équipés de réglages de pression ajustables pour réaliser efficacement différentes tâches de nettoyage.

Un nettoyage à haute pression peut-il endommager les surfaces ?

Oui, un nettoyeur haute pression peut endommager les surfaces s'il est mal utilisé. L'eau à haute pression peut décaper la peinture, bosseler les surfaces fragiles, voire causer des dommages structurels si la pression est trop élevée ou si la buse est tenue trop près de la surface. Utilisez toujours la pression adaptée au matériau à nettoyer et maintenez une distance de sécurité avec les surfaces délicates.

Pour éviter tout dommage, envisagez d'utiliser un modèle avec des réglages de pression ajustables.

Comment entretenir votre nettoyeur haute pression ?

Pour garantir la durabilité et le bon fonctionnement d'un nettoyeur haute pression :

- Changez l'huile conformément aux instructions du fabricant.

- Nettoyez ou remplacez le filtre à air pour assurer une bonne circulation de l'air.

- Inspectez et nettoyez régulièrement la buse pour éviter les obstructions.

- Vidangez le réservoir d'essence si vous rangez la machine à laver pendant une longue période.

- Vérifiez l'étanchéité et l'état des tuyaux et remplacez-les si nécessaire.

- Respectez les consignes d'entretien régulier pour maintenir la machine à laver en parfait état.

Puis-je utiliser un nettoyeur haute pression par temps froid et lorsque l'eau est basse ?

Il est possible d'utiliser un nettoyeur haute pression par temps froid, mais cela s'avère plus délicat. Le débit d'eau dans les tuyaux et la pompe peut geler et endommager l'appareil. Si vous prévoyez d'utiliser votre nettoyeur haute pression par temps froid, veillez à le préparer pour l'hiver et à le ranger dans un endroit chaud lorsqu'il n'est pas utilisé. Vous pouvez également utiliser des solutions antigel pour nettoyeurs haute pression.

Certains modèles sont conçus pour utiliser de l'eau chaude, ce qui peut s'avérer particulièrement efficace pour le nettoyage par temps froid.

Ai-je besoin d'accessoires ?

Accessoires courants pour nettoyeurs haute pression :

- Différentes buses (0°, 15°, 25°, 40° et buse à savon) pour ajuster les motifs de pulvérisation.

- Rallonges pour les zones difficiles d'accès.

- Nettoyants de surface pour grandes surfaces planes comme les allées et les terrasses.

- Enrouleurs de tuyau pour ranger les tuyaux proprement et éviter qu'ils ne s'emmêlent.

- Canon à mousse ou bouteilles de détergent pour savon ou solutions de nettoyage.

- Détergents pour le nettoyage d'une grande variété de surfaces .