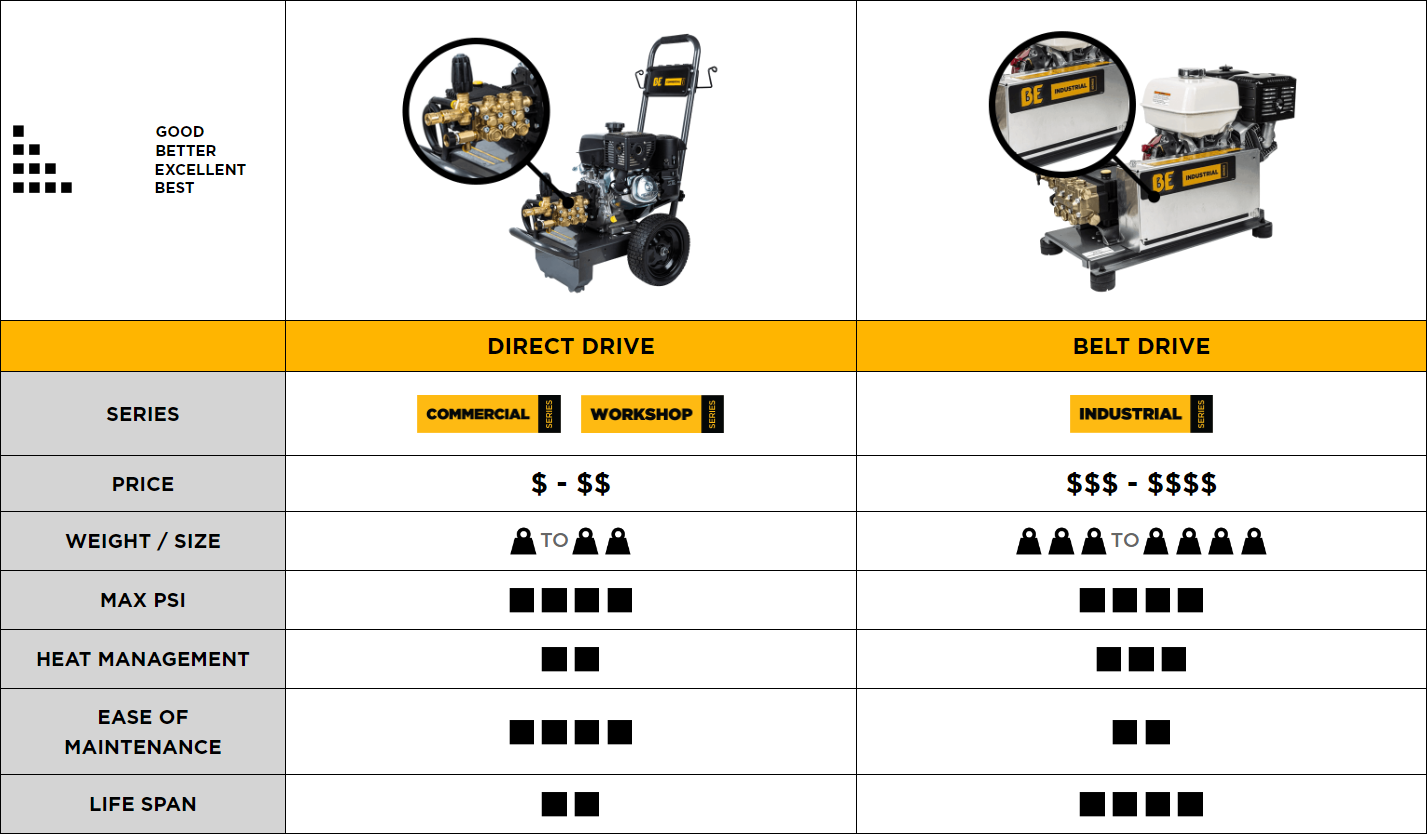

SYSTÈMES D'ENTRAÎNEMENT

Une pompe à entraînement direct possède un arbre creux qui s'emboîte simplement sur l'arbre moteur. La bride de la pompe est fixée à la face du moteur ou à l'extrémité de son arbre. Le régime moteur normal d'un moteur à essence est d'environ 3 450 tr/min. La pompe étant directement reliée à l'arbre moteur, son régime est identique à celui du moteur.

Une pompe à entraînement par courroie possède une poulie fixée à son arbre rigide et est entraînée par une ou plusieurs courroies reliées à une poulie du moteur. Ce système de poulies permet à ces pompes de tourner à un régime beaucoup plus bas qu'une pompe à entraînement direct (généralement entre 900 et 1 740 tr/min). Le carter d'huile d'une pompe à entraînement par courroie offre une plus grande capacité. Ceci, combiné au régime plus bas de la pompe, lui permet de fonctionner à une température bien inférieure à celle d'une pompe à entraînement direct.

GUIDE DES SYSTÈMES D'ENTRAÎNEMENT

Avantages de la transmission directe

- Conception compacte

- Moins de pièces mobiles

- coût inférieur

- Très peu d'entretien

Avantages de la transmission par courroie

- Meilleure gestion de la chaleur

- Transfert de vibrations réduit

- Régime moteur inférieur

- Durée de vie plus longue