PRODUCT

DESCRIPTION

The power to push limits — engineered for precision, built for endurance, and trusted by professionals worldwide.

Built for Extreme Pressure and Peak Performance

The Centurion P11 Belt Drive Triplex Pump (85.120.159B) represents the highest echelon of commercial and industrial pressure washer pump technology. Designed and manufactured by CP, a world-class leader in pump engineering, the P11 is purpose-built for contractors, industrial maintenance crews, and facility operators who demand uncompromising power and durability.

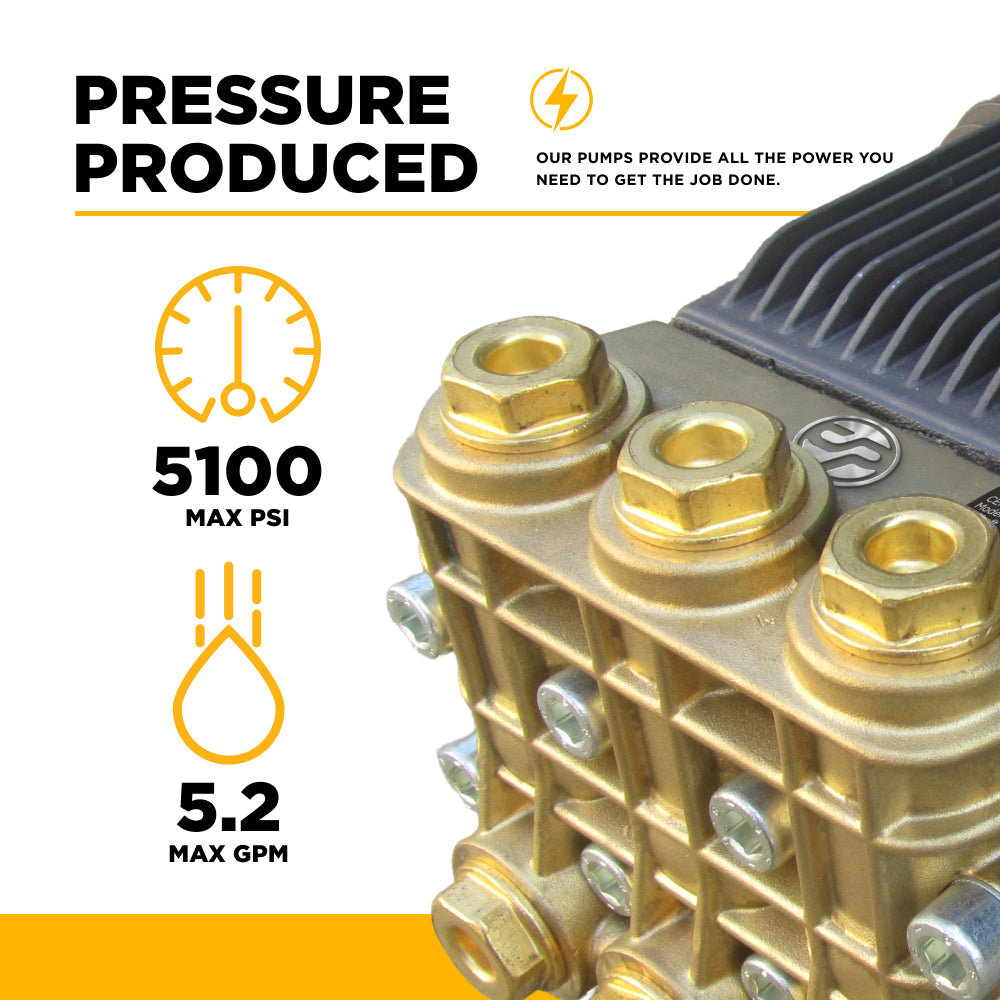

Delivering an exceptional 5,100 PSI at 5.2 GPM, this pump combines massive cleaning power with efficient, low-RPM operation. The result is a system that runs cooler, quieter, and longer — the hallmark of professional-grade performance.

With a belt drive system, brass manifold, ceramic plungers, and an external unloader, the Centurion P11 provides consistent high-pressure performance without the wear, vibration, or overheating that plague standard direct-drive pumps. Whether paired with a gas or electric motor, the P11’s heavy-duty build and precision design make it the trusted heart of your professional cleaning system.

Technical Overview

-

PMR PART #: 85.129.159B

-

BARE PUMP PART #: 85.120.159B

-

PUMP MANUFACTURER: CP

-

PUMP MODEL: CTB3S

-

DRIVE TYPE: Belt Drive (Gas / Electric Compatible)

-

SHAFT SIZE: 24 mm

-

PUMP STYLE: Triplex

-

MAX PSI: 5,100

-

MAX GPM: 5.2

-

UNLOADER TYPE: External

-

PLUNGER (PISTON): Ceramic

-

INLET SIZE: 3/4" GHF

-

DISCHARGE SIZE: 3/8" Stainless Steel QC

-

SOAP INJECTOR: Adjustable

-

MANIFOLD TYPE: Brass

-

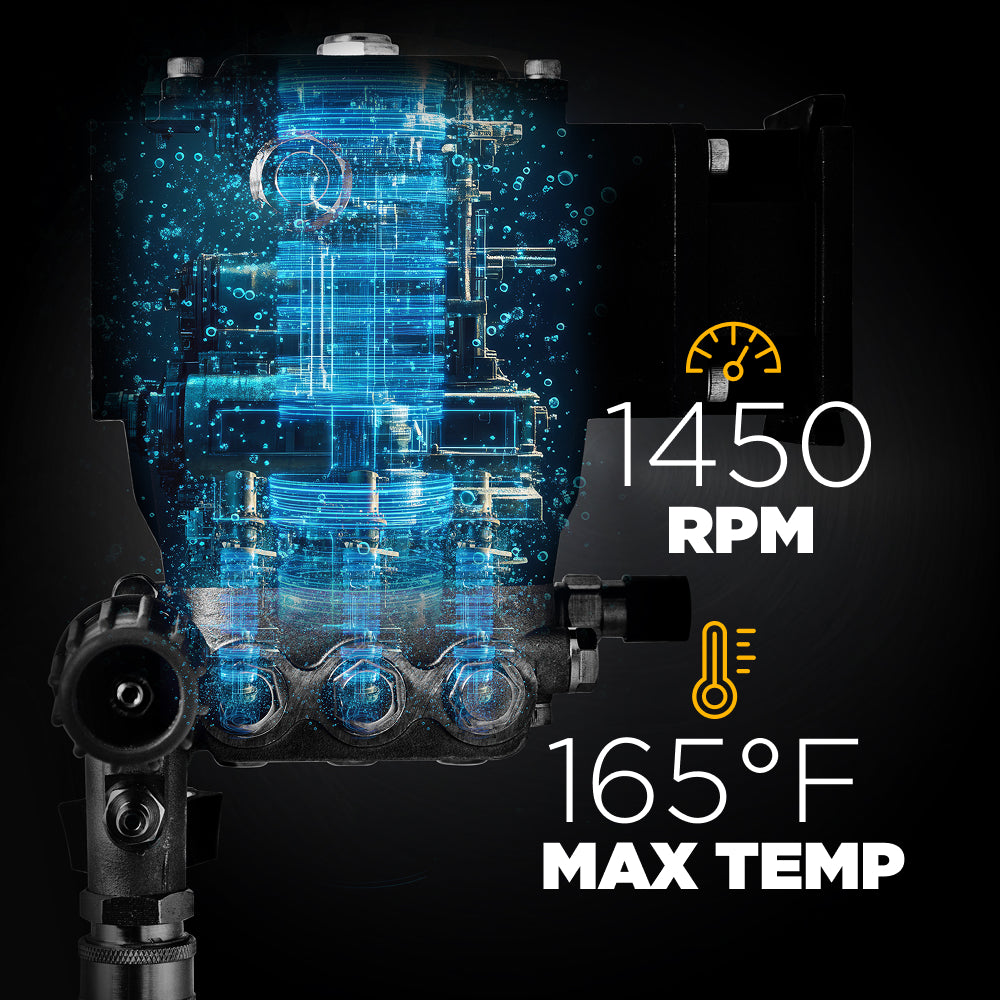

RPM: 1,450

-

MAX INLET TEMP: 60°C / 140°F

-

THERMAL RELIEF VALVE: 85.300.024

-

OIL CAPACITY: 37 fl oz

-

OIL TYPE: 30W Non-Detergent

-

WEIGHT: 46 lbs

-

WARRANTY: 7 Years

Engineered for Professionals

At 5,100 PSI, the Centurion P11 is one of the most powerful belt-drive pumps in its class — delivering cleaning force strong enough to cut through heavy grease, industrial residue, concrete buildup, and even layers of paint or rust. Despite its brute strength, it’s built for precision, offering consistent, balanced pressure output that’s smooth and easy to control.

Designed to operate at a low 1,450 RPM, this pump reduces wear on internal components and stays cool during extended operation. Its belt drive configuration isolates the engine from vibration, protects the crankshaft from misalignment, and ensures quieter, more stable performance — perfect for professional applications that demand both power and reliability.

From construction sites to industrial plants, the P11 delivers the dependable cleaning performance professionals need to get the job done faster, cleaner, and safer.

Key Features

Triplex Ceramic Plunger Design

The P11 features a triplex plunger pump with three precision-engineered ceramic pistons, each designed for maximum strength and heat resistance. Ceramic is the material of choice for high-end industrial pumps because it resists corrosion, reduces friction, and dissipates heat efficiently — ensuring cooler, smoother operation over thousands of hours.

This triplex system ensures a steady flow of water with minimal pulsation, delivering consistent pressure even under fluctuating load conditions. It’s the secret to the P11’s stable performance and extended service life.

Heavy-Duty Brass Manifold

The brass manifold provides unmatched strength and corrosion resistance, crucial for handling high pressure and continuous exposure to water, detergents, and chemicals. Brass outperforms cast aluminum or cheaper alloys by maintaining its structural integrity over time — resisting warping, pitting, and internal leaks.

The manifold’s precision machining ensures perfect sealing, reducing maintenance and preventing costly downtime.

External Unloader System

The external unloader gives operators precise control over system pressure while simplifying maintenance and replacement. Located outside the pump body for easy access, it allows adjustments to suit different cleaning applications — from gentle washing to aggressive stripping.

External unloaders also enhance cooling during bypass mode, preventing the pump from overheating when the trigger is released for extended periods.

Adjustable Soap Injector

The adjustable soap injector allows precise control of chemical draw, letting users fine-tune detergent concentration for specific cleaning tasks. Whether you’re degreasing engines, disinfecting food-processing equipment, or restoring building exteriors, the P11’s injector makes it easy to switch between chemical application and high-pressure rinse without losing momentum.

Stainless Steel Quick Connect Discharge

Unlike standard brass fittings, the stainless steel 3/8" QC discharge is designed for extreme durability and corrosion resistance. It ensures a secure, leak-free connection that withstands high pressure and long-term exposure to detergents or saltwater environments — ideal for marine or industrial applications.

Thermal Relief Valve (85.300.024)

Protecting the pump from overheating, the thermal relief valve automatically opens to release overheated water during bypass operation, drawing in cooler water to stabilize temperature. This essential feature preserves seals and valves, extending pump longevity in demanding professional use.

High Oil Capacity Crankcase

With a 37 fl oz oil capacity, the P11’s crankcase provides continuous, clean lubrication for all moving components. The 30W non-detergent oil minimizes foaming and oxidation, maintaining consistent viscosity even under high load and temperature conditions.

This generous oil capacity also extends service intervals, allowing for long operation between maintenance cycles — reducing downtime and operating costs.

Belt Drive: The Professional Standard

The belt drive configuration is what separates the Centurion P11 from lighter-duty pumps. This design decouples the pump from the motor or engine, absorbing vibration, reducing mechanical stress, and lowering the operating RPM.

Advantages of Belt Drive Systems:

-

Extended Life: Lower operating speed means reduced heat and wear.

-

Cooler Operation: Airflow and belt tension dissipate heat efficiently.

-

Quieter Performance: Ideal for professional facilities and work environments.

-

Flexibility: Compatible with both gas engines and electric motors.

-

Reduced Maintenance: Fewer internal failures compared to direct drive designs.

At 1,450 RPM, the P11 delivers the same power as faster direct drive pumps but with far greater longevity and smoother, quieter performance.

Built for Heavy-Duty Industrial Applications

The P11’s flow rate and pressure output make it an exceptional fit for a wide range of demanding applications. Its balanced design ensures consistent performance across varied operating conditions, from high-pressure washing to large-scale industrial cleaning.

Typical Applications Include:

-

Fleet & Vehicle Washing: Easily removes oil, road salt, and grime from trucks, buses, and heavy equipment.

-

Concrete & Surface Cleaning: Blasts away buildup, paint, and debris without surface damage.

-

Industrial Equipment Maintenance: Keeps machines, conveyors, and tools free of residue and buildup.

-

Agriculture: Cleans tractors, harvesters, and barns with powerful, efficient water delivery.

-

Manufacturing Plants: Maintains cleanliness and safety standards in production environments.

-

Marine Applications: Withstands saltwater exposure while cleaning ships, docks, and port equipment.

From car wash systems to factory cleaning stations, the Centurion P11 provides a reliable power source that professionals depend on every day.

Durable Construction and Long-Term Value

The Centurion P11 is more than powerful — it’s built to outlast and outperform. With precision-machined components, heavy-duty bearings, and reinforced seals, it’s designed for years of service under punishing conditions.

Durability Features:

-

Hardened crankshaft for strength and vibration resistance.

-

Oversized connecting rods for smoother operation.

-

Premium seals to prevent leaks under extreme pressure.

-

Heat-resistant plungers and gaskets for extended reliability.

-

Corrosion-resistant brass and stainless-steel fittings throughout.

Every pump is pressure-tested and quality-assured before shipment, ensuring you receive a perfectly balanced unit ready to perform from day one.

Maintenance Simplified

Professional-grade performance doesn’t have to come with complicated maintenance. The P11’s design makes it easy to inspect, adjust, and service key components without disassembly or specialized tools.

Recommended Maintenance Routine:

-

Check oil level before each use; change after the first 50 hours, then every 500 hours.

-

Inspect drive belts for proper tension and wear.

-

Keep inlet filters clean and debris-free.

-

Flush the chemical injector after each use to prevent buildup.

-

Test unloader and thermal relief valve regularly to ensure correct operation.

Routine care keeps your P11 running at peak performance, minimizing downtime and maximizing return on investment.

High-Temperature Capability

The P11’s maximum inlet temperature of 60°C (140°F) allows it to handle warm water applications safely, enhancing its cleaning versatility. Warmer water helps dissolve grease and oil more efficiently, making the P11 ideal for degreasing and sanitizing tasks in commercial kitchens, manufacturing facilities, or agricultural environments.

When paired with a compatible heating system, this capability boosts cleaning power without increasing chemical usage — an eco-friendly and cost-effective advantage.

Installation and Compatibility

The P11’s 24 mm solid shaft and standard bolt pattern make it simple to integrate with most commercial gas engines and electric motors. Ideal for OEM systems or replacements, its flexibility supports a wide range of configurations.

Installation Guidelines:

-

Mount the pump securely on a stable, vibration-free surface.

-

Align pulleys and belts precisely to prevent uneven wear.

-

Connect the 3/4" GHF inlet and 3/8" stainless steel QC discharge fittings.

-

Fill with 37 fl oz of 30W non-detergent oil before startup.

-

Prime the system with clean water to remove air pockets.

-

Adjust unloader to the desired pressure setting.

Once installed, the P11 provides smooth, consistent operation — ready for years of reliable service.

Backed by a 7-Year Warranty

Every Centurion pump is backed by a 7-year limited manufacturer’s warranty, underscoring CP’s confidence in its craftsmanship and engineering excellence. Each pump is pressure-tested, flow-verified, and quality-inspected to ensure it meets exacting standards before leaving the factory.

This warranty isn’t just a promise — it’s proof that the P11 is built to endure the rigors of daily professional use while maintaining consistent, high-quality performance.

Product Highlights

-

Model: CTB3S (Centurion P11)

-

PMR Part #: 85.129.159B

-

Bare Pump #: 85.120.159B

-

Drive Type: Belt Drive (Gas / Electric)

-

Pressure / Flow: 5,100 PSI @ 5.2 GPM

-

RPM: 1,450

-

Manifold: Brass

-

Plungers: Ceramic

-

Unloader: External Adjustable

-

Soap Injector: Adjustable

-

Discharge Fitting: 3/8" Stainless Steel Quick Connect

-

Thermal Relief Valve: 85.300.024

-

Oil Capacity: 37 fl oz (30W Non-Detergent)

-

Weight: 46 lbs

-

Warranty: 7 Years

The Centurion P11 Belt Drive Triplex 5100 PSI 5.2 GPM Pressure Washer Bare Pump (85.120.159B) is a professional-grade powerhouse built for extreme cleaning performance. Featuring a brass manifold, ceramic plungers, external unloader, and stainless-steel discharge fittings, it delivers smooth, reliable power under continuous-duty conditions.

Operating at a low 1,450 RPM, the P11 runs cool and quiet, extending its lifespan well beyond typical commercial pumps. Its belt drive system ensures reduced vibration and long-term reliability, while its 7-year warranty provides peace of mind for the most demanding applications.

Centurion P11 — When maximum pressure meets maximum durability, professionals trust nothing less.

Frequently Asked Questions about Pressure Washers

How to store a pressure washer?

To ensure the durability of your heavy duty pressure washer:

- Empty the gas tank to prevent fuel from degrading or clogging the engine.

- Empty the pump and hoses of any remaining water.

- Perform necessary maintenance before storage.

- Store in a dry area.

- Cover.

What is a pressure washer?

A power washer is a cleaning machine that uses a gasoline engine to power a high pressure water pump and nozzle. It’s used to clean driveways, decks, vehicles, outdoor furniture and more by spraying water at high PSI to remove dirt, grime, mold and other debris.Many models also come with a detergent tank for added cleaning power.

How does a power washer work?

A power washer works by drawing water from a connected hose and pumping it through a high pressure nozzle. The gas engine powers the pump which pressurizes the water and then expels it through the nozzle at high speed to clean the surface. The water pressure is measured in PSI (pounds per square inch) and the flow rate is measured in GPM (gallons per minute).Many models also feature adjustable water pressure settings to cater to different cleaning needs. BE makes pressure washing easy with models available for light jobs and heavy duty commercial cleaning projects.

Gas vs Electric power washers?

The main difference is that a gas pressure washer, known for its cleaning power, is powered by a gasoline engine, making it more powerful and portable, while an electric pressure washer is powered by electricity and is generally quieter and lighter.

Gas pressure washers are for heavy duty and large areas due to their durability, whereas electric pressure washers are for smaller jobs.

Your BE electric pressure washer is perfect for smaller jobs and built for portability, and we offer a wide range of electric models. Included with our electric models is a long extension cord for use anywhere around your house.

What to consider?

When choosing a gas pressure washer consider:

- Pressure (PSI): More PSI means more cleaning power but also more potential for damaging delicate surfaces.

- Flow Rate (GPM): More GPM means faster cleaning as more water is dispensed.

- Engine Power: Bigger engines mean more durability and power.

- Portability: Weight, handle design and wheel size for easier to move.

- Nozzles: Multiple spray nozzles to adjust the spray pattern for different tasks.

- Adjustable Nozzle: Allows for fine-tuning the spray intensity and pattern for various cleaning needs.

How much pressure do I need for?

The required pressure (PSI) and cleaning power depend on the surface you’re cleaning:

- Light duty (car washing, outdoor furniture): 1,300-1,800 PSI.

- Medium duty (patios, fences, decks): 2,000-3,000 PSI.

- Heavy duty (driveways, brick walls, large equipment): 3,000+ PSI.

Many pressure washers come with adjustable pressure settings to handle different cleaning tasks effectively.

Can a pressure washing damage surfaces?

Yes, a power washer can damage surfaces if used incorrectly. High pressure water can strip paint, dent soft surfaces or even cause structural damage if the pressure is too high or the nozzle is held too close to the surface. Always use the right PSI for the material you’re cleaning and keep a safe distance from delicate surfaces.

To prevent damage, consider using a model with adjustable pressure settings.

How to maintain your pressure washer?

To ensure the durability and smooth operation of a pressure washer:

- Change the oil as per manufacturer’s instructions.

- Clean or replace the air filter to ensure good airflow.

- Inspect and clean the nozzle regularly to prevent clogs.

- Drain the gas tank if you’re storing the washer for a long time.

- Check the hoses for leaks or damage and replace them if needed.

- Follow regular maintenance requirements to keep the washer in optimal condition.

Can I use a pressure washer in cold weather and low water temperature?

You can use a pressure washer in cold weather but it’s more difficult. The water flow rate in the hoses and pump can freeze and damage the equipment. If you plan to use your pressure washer in cold temperatures make sure to winterize it and store it in a warm area when not in use. You can also use anti-freeze solutions for pressure washers.

Some models are designed to use hot water, which can be particularly effective for cleaning in cold weather.

Do I need any accessories?

Common accessories for power washers:

- Different nozzles (0°, 15°, 25°, 40°, and soap nozzle) to adjust spray patterns.

- Extension wands for hard to reach areas.

- Surface cleaners for large flat areas like driveways and decks.

- Hose reels to store hoses neatly and prevent tangling.

- Foam cannon or detergent bottles for soap or cleaning solutions.

- Detergents for cleaning a wide variety of surfaces.