PRODUCT

DESCRIPTION

Professional-grade power. Industrial durability. Engineered for performance that lasts.

Unleash Industrial Power with Unmatched Precision

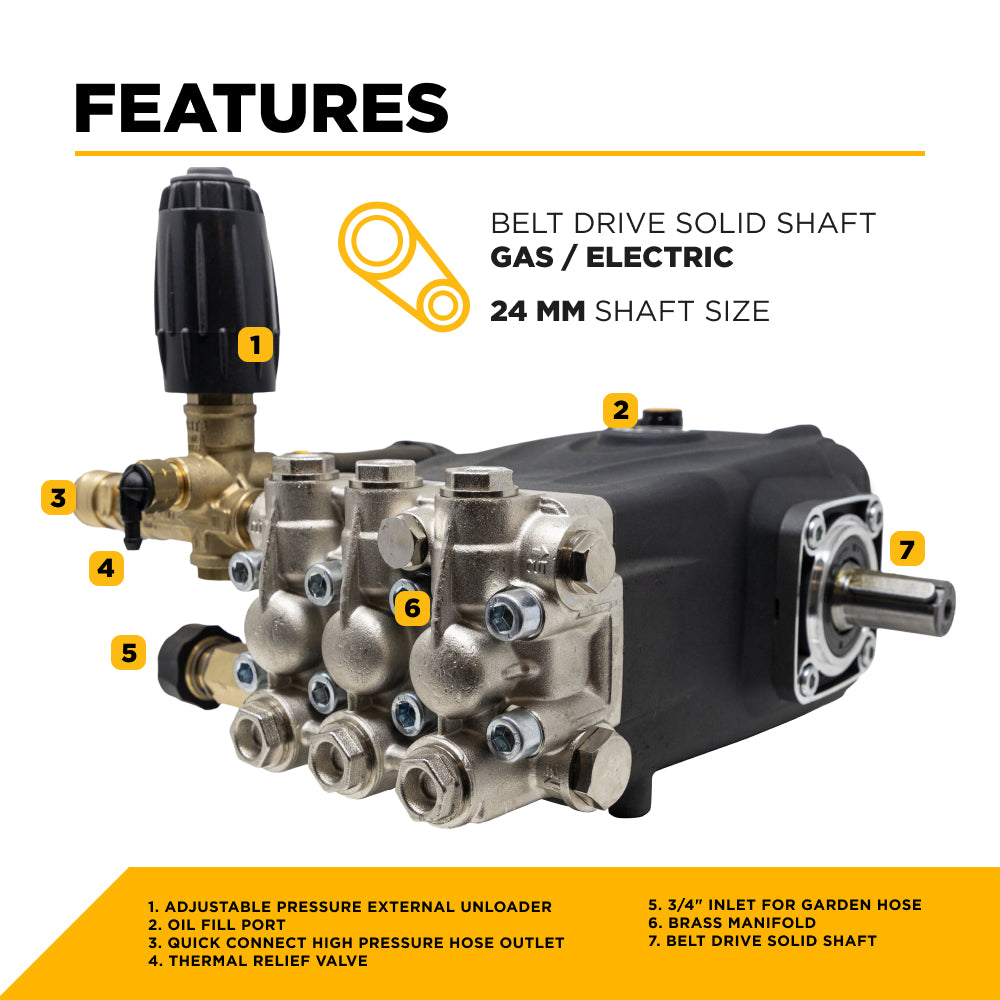

The Centurion P8 Belt Drive Triplex Pump (85.120.106B) represents the pinnacle of professional pressure washer engineering. Manufactured by CP, a global leader in high-pressure pump technology, this model is built to perform in the most demanding cleaning environments. Designed for gas or electric-powered systems, it delivers a commanding 4,000 PSI of pressure at 4.0 GPM, making it ideal for contractors, industrial maintenance professionals, and equipment manufacturers who demand exceptional performance and reliability.

With a belt-driven system running at 1,450 RPM, the P8 operates cooler, quieter, and longer than conventional direct-drive units. Its nickel-plated brass manifold, ceramic plungers, and external unloader provide the foundation for smooth operation, corrosion resistance, and extended service life. Whether you're cleaning commercial fleets, construction equipment, or large-scale industrial surfaces, the Centurion P8 is engineered to handle it with precision and strength.

Technical Overview

-

PMR PART #: 85.129.106B

-

BARE PUMP PART #: 85.120.106B

-

PUMP MANUFACTURER: CP

-

PUMP MODEL: CTB1S

-

DRIVE TYPE: Belt Drive (Gas / Electric)

-

SHAFT SIZE: 24 mm

-

PUMP STYLE: Triplex

-

MAX PSI: 4,000

-

MAX GPM: 4.0

-

UNLOADER TYPE: External

-

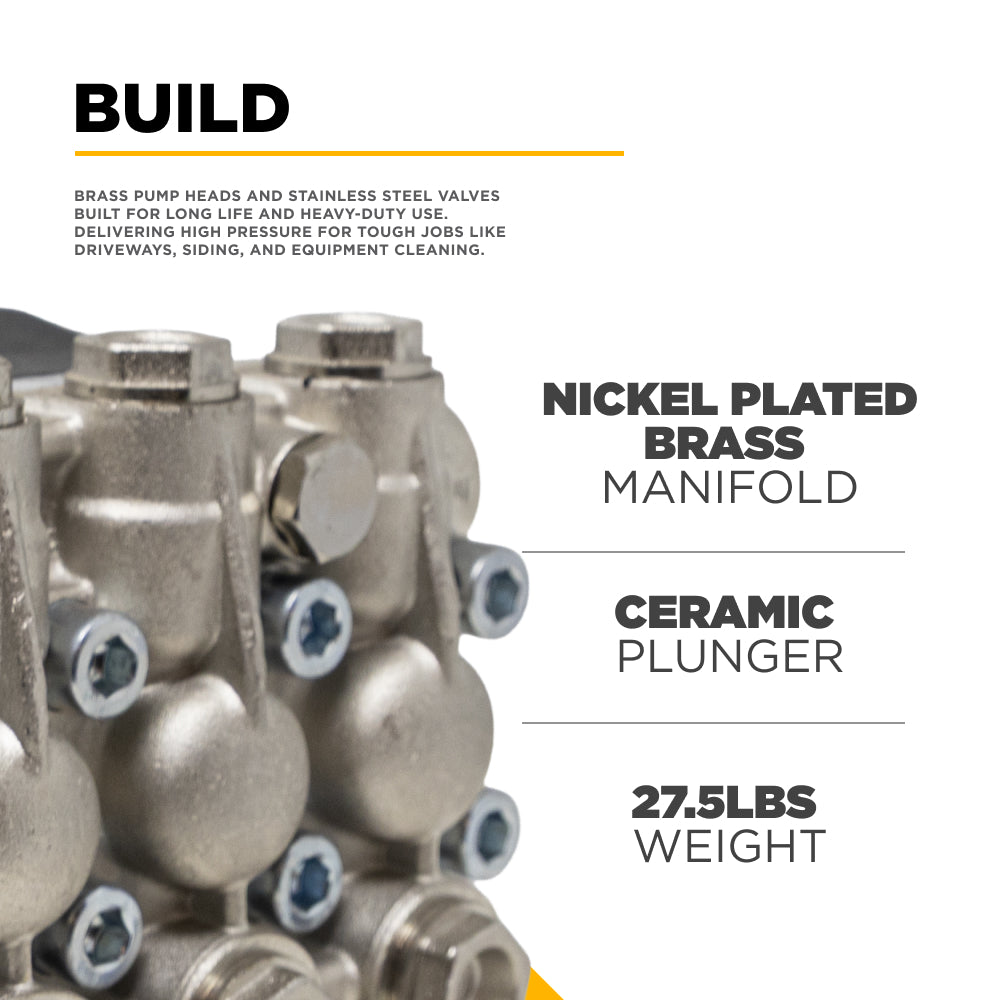

PLUNGER (PISTON): Ceramic

-

INLET SIZE: 3/4" GHF

-

DISCHARGE SIZE: 3/8" Brass Quick Connect

-

SOAP INJECTOR: Adjustable

-

MANIFOLD TYPE: Nickel-Plated Brass

-

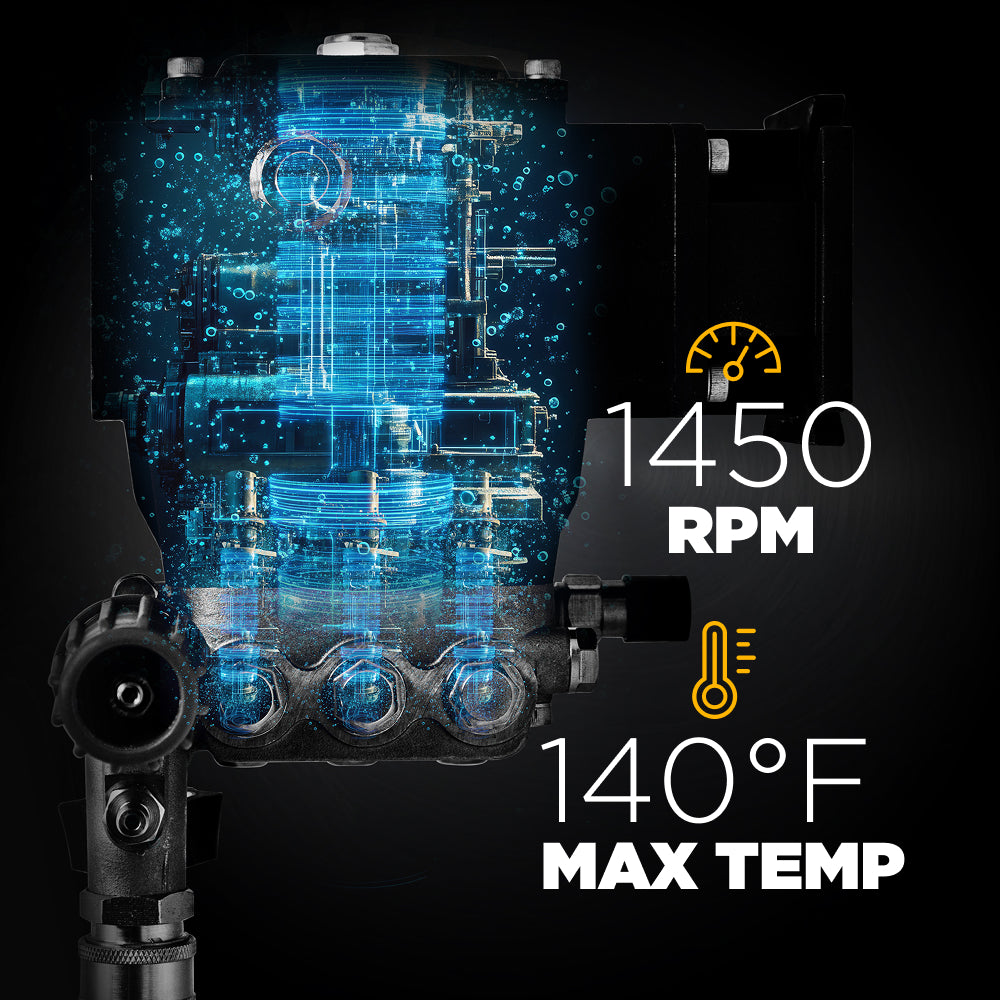

RPM: 1,450

-

MAX INLET TEMP: 60°C / 140°F

-

THERMAL RELIEF VALVE: 85.300.024

-

OIL CAPACITY: 32 fl oz

-

OIL TYPE: 30W Non-Detergent

-

WEIGHT: 27.5 lbs

-

WARRANTY: 7 Years

Built for Industrial-Grade Cleaning

The Centurion P8 (CTB1S) isn’t just powerful — it’s purpose-built. Its 4,000 PSI pressure output delivers enough cleaning force to strip paint, cut through grease, and remove hardened grime from the toughest surfaces. The 4.0 GPM flow rate provides excellent coverage and rinsing capability, striking a perfect balance between cleaning efficiency and controlled precision.

This pump is the ideal choice for applications where uptime, longevity, and consistent performance are critical. From mobile wash trailers to fixed industrial systems, the Centurion P8 provides the power professionals rely on to get every job done quickly, safely, and efficiently.

Key Features

Triplex Ceramic Plunger Design

At the heart of the Centurion P8 is a precision triplex plunger system, which uses three ceramic pistons to generate smooth, pulse-free flow. Ceramic offers exceptional hardness and thermal resistance, minimizing friction and wear even during prolonged operation. This ensures not only steady performance but also reduced maintenance costs over the lifespan of the pump.

Nickel-Plated Brass Manifold

The nickel-plated brass manifold is built for longevity in harsh environments. Nickel plating provides an extra layer of protection against corrosion, oxidation, and chemical exposure, making the pump ideal for industrial use, including chemical washdowns and marine applications. Unlike cheaper aluminum components, the brass body ensures rigidity and perfect sealing under high pressure.

External Unloader for Precise Control

The external unloader valve offers easy pressure adjustment and fast access for servicing or replacement. It provides full control of pressure output, enabling operators to fine-tune performance for different cleaning tasks — from low-pressure rinsing to aggressive surface blasting. The unloader also contributes to thermal management by improving water recirculation during bypass cycles.

Adjustable Soap Injector

The adjustable soap injector allows users to control the draw and concentration of cleaning solutions precisely. This gives full flexibility for switching between detergent application and high-pressure rinse, maximizing efficiency and chemical economy during every cleaning session.

Thermal Relief Valve Protection

The thermal relief valve (85.300.024) protects the pump from heat damage during idle or bypass operation by automatically releasing overheated water and drawing in cooler water. This simple yet essential component ensures continuous safe operation and extends seal and valve life.

High Oil Capacity for Superior Lubrication

With a 32 fl oz oil capacity, the P8’s crankcase provides superior lubrication and thermal dissipation. The 30W non-detergent oil reduces foaming and oxidation, protecting the internal components from wear and ensuring smooth operation, even under high load and extended use.

Belt Drive: The Professional Advantage

The Centurion P8 uses a belt drive system that separates the pump from the engine or motor, allowing for slower, cooler operation and dramatically extending the pump’s lifespan.

Key Benefits of Belt Drive Pumps:

-

Lower RPM (1,450): Reduces heat buildup and extends bearing and seal life.

-

Vibration Isolation: Belts absorb engine vibration, reducing stress on pump components.

-

Quieter Operation: Ideal for professional and industrial environments.

-

Longer Life Expectancy: Typically doubles the lifespan of direct-drive pumps.

-

Flexible Compatibility: Works with both gas engines and electric motors.

Whether you’re outfitting a stationary wash bay or a portable skid system, the belt drive design ensures reliable, steady operation even during long, continuous cleaning sessions.

Built for Longevity and Professional Use

Every element of the Centurion P8 is designed for endurance under demanding workloads. From precision bearings and hardened steel crankshafts to its nickel-plated manifold and ceramic plungers, the P8 is engineered to withstand years of rigorous use in industrial, commercial, and municipal cleaning applications.

Durability Highlights:

-

Hardened steel crankshaft for superior strength and balance.

-

Oversized bearings and seals designed for continuous duty.

-

High-quality gaskets for leak-free operation under pressure.

-

Corrosion-resistant materials suitable for all climates.

-

Factory pressure-tested to ensure reliable performance out of the box.

This combination of materials and craftsmanship ensures that the P8 consistently delivers professional results, job after job.

Smooth, Quiet, and Efficient Operation

Operating at 1,450 RPM, the P8 runs significantly quieter and cooler than high-speed direct-drive pumps. The low-speed operation reduces cavitation risk, minimizes wear on internal seals, and enhances long-term performance.

This efficiency translates to:

-

Cooler running temperature — ideal for long-duty cycles.

-

Reduced vibration — preventing premature component fatigue.

-

Extended maintenance intervals — saving time and operating costs.

For professionals who demand reliable, consistent power without excessive noise or heat, the Centurion P8 stands out as the superior choice.

Performance That Delivers Results

With 4,000 PSI and 4.0 GPM, the P8 delivers exceptional performance for medium to heavy-duty cleaning applications. Its flow-to-pressure ratio is optimized for powerful yet controlled cleaning, making it suitable for a variety of tasks, including:

-

Fleet and Equipment Washing: Removes road grime, oil, and debris efficiently.

-

Concrete and Building Cleaning: Restores surfaces by removing mold, grease, and stains.

-

Agricultural Cleaning: Maintains farm equipment and barns in top condition.

-

Construction and Restoration: Cleans tools, machinery, and job sites with ease.

-

Industrial and Municipal Applications: Ideal for sanitation, maintenance, and washdown systems.

Whatever the challenge, the Centurion P8 provides the high-pressure performance and reliability needed to tackle it head-on.

Easy Installation and Compatibility

The P8’s 24 mm solid shaft and compact frame design make it compatible with a wide range of belt-driven gas and electric systems.

Installation Overview:

-

Mount the pump securely to a flat, stable base.

-

Align and tension the belt system properly to prevent slippage.

-

Connect the 3/4" GHF inlet to a filtered water source.

-

Attach the 3/8" brass quick-connect discharge fitting to your pressure line.

-

Fill the crankcase with 32 fl oz of 30W non-detergent oil before starting.

-

Prime the system and check for leaks before operation.

Once installed, the P8 is ready for years of dependable service with minimal maintenance required.

Maintenance Made Simple

The Centurion P8’s design prioritizes serviceability. The external unloader, oil sight glass, and accessible components make routine maintenance straightforward — ensuring you spend more time cleaning and less time in the workshop.

Maintenance Schedule:

-

Oil Change: After the first 50 hours, then every 500 hours or 3 months.

-

Check Belts: Inspect tension and alignment regularly.

-

Inspect Seals and Valves: Replace as needed to maintain performance.

-

Flush Chemical Injector: After every detergent use to prevent buildup.

-

Clean Inlet Filter: Regularly to avoid debris damage.

By following these steps, you’ll ensure that your Centurion P8 continues to perform flawlessly over thousands of operating hours.

Built for Real-World Professionals

The Centurion P8 isn’t designed for occasional use — it’s built for professionals who depend on their equipment day in and day out. From the robust brass and ceramic construction to the low-RPM operation, every element is engineered to ensure consistent, reliable performance under continuous workloads.

Why Professionals Choose the P8:

-

Built for 24/7 operation in industrial environments.

-

Runs cooler and quieter for user comfort and safety.

-

Outlasts standard pumps with superior materials and craftsmanship.

-

Backed by a 7-year manufacturer’s warranty — among the best in the industry.

When uptime, productivity, and performance are critical, the Centurion P8 delivers — job after job, year after year.

Backed by a 7-Year Warranty

The Centurion P8 Belt Drive Triplex Pump is backed by a 7-year manufacturer’s warranty, underscoring CP’s commitment to excellence. Each pump undergoes rigorous testing for pressure stability, flow accuracy, and seal integrity before leaving the factory.

This long-term warranty ensures complete peace of mind and demonstrates the confidence CP places in its engineering, materials, and craftsmanship.

Product Highlights

-

Model: CTB1S (Centurion P8)

-

PMR Part #: 85.129.106B

-

Bare Pump #: 85.120.106B

-

Drive Type: Belt Drive (Gas / Electric Compatible)

-

Pressure / Flow: 4,000 PSI @ 4.0 GPM

-

RPM: 1,450

-

Manifold: Nickel-Plated Brass

-

Plungers: Ceramic

-

Unloader: External Adjustable

-

Soap Injector: Adjustable

-

Thermal Relief Valve: 85.300.024

-

Oil Capacity: 32 fl oz (30W Non-Detergent)

-

Weight: 27.5 lbs

-

Warranty: 7 Years

The Centurion P8 Belt Drive Triplex 4000 PSI 4.0 GPM Pressure Washer Bare Pump (85.120.106B) delivers industrial-grade power, precision, and durability. With its nickel-plated brass manifold, ceramic plungers, external unloader, and belt-driven 1,450 RPM design, this pump runs cooler, quieter, and longer than conventional units.

Whether used in mobile wash systems, commercial cleaning setups, or industrial facilities, the P8 offers unmatched reliability and performance. Backed by a 7-year warranty, it’s built to handle the toughest jobs — day after day, year after year.

Centurion P8 — Built stronger. Engineered smarter. Trusted by professionals everywhere.

Frequently Asked Questions about Pressure Washers

How to store a pressure washer?

To ensure the durability of your heavy duty pressure washer:

- Empty the gas tank to prevent fuel from degrading or clogging the engine.

- Empty the pump and hoses of any remaining water.

- Perform necessary maintenance before storage.

- Store in a dry area.

- Cover.

What is a pressure washer?

A power washer is a cleaning machine that uses a gasoline engine to power a high pressure water pump and nozzle. It’s used to clean driveways, decks, vehicles, outdoor furniture and more by spraying water at high PSI to remove dirt, grime, mold and other debris.Many models also come with a detergent tank for added cleaning power.

How does a power washer work?

A power washer works by drawing water from a connected hose and pumping it through a high pressure nozzle. The gas engine powers the pump which pressurizes the water and then expels it through the nozzle at high speed to clean the surface. The water pressure is measured in PSI (pounds per square inch) and the flow rate is measured in GPM (gallons per minute).Many models also feature adjustable water pressure settings to cater to different cleaning needs. BE makes pressure washing easy with models available for light jobs and heavy duty commercial cleaning projects.

Gas vs Electric power washers?

The main difference is that a gas pressure washer, known for its cleaning power, is powered by a gasoline engine, making it more powerful and portable, while an electric pressure washer is powered by electricity and is generally quieter and lighter.

Gas pressure washers are for heavy duty and large areas due to their durability, whereas electric pressure washers are for smaller jobs.

Your BE electric pressure washer is perfect for smaller jobs and built for portability, and we offer a wide range of electric models. Included with our electric models is a long extension cord for use anywhere around your house.

What to consider?

When choosing a gas pressure washer consider:

- Pressure (PSI): More PSI means more cleaning power but also more potential for damaging delicate surfaces.

- Flow Rate (GPM): More GPM means faster cleaning as more water is dispensed.

- Engine Power: Bigger engines mean more durability and power.

- Portability: Weight, handle design and wheel size for easier to move.

- Nozzles: Multiple spray nozzles to adjust the spray pattern for different tasks.

- Adjustable Nozzle: Allows for fine-tuning the spray intensity and pattern for various cleaning needs.

How much pressure do I need for?

The required pressure (PSI) and cleaning power depend on the surface you’re cleaning:

- Light duty (car washing, outdoor furniture): 1,300-1,800 PSI.

- Medium duty (patios, fences, decks): 2,000-3,000 PSI.

- Heavy duty (driveways, brick walls, large equipment): 3,000+ PSI.

Many pressure washers come with adjustable pressure settings to handle different cleaning tasks effectively.

Can a pressure washing damage surfaces?

Yes, a power washer can damage surfaces if used incorrectly. High pressure water can strip paint, dent soft surfaces or even cause structural damage if the pressure is too high or the nozzle is held too close to the surface. Always use the right PSI for the material you’re cleaning and keep a safe distance from delicate surfaces.

To prevent damage, consider using a model with adjustable pressure settings.

How to maintain your pressure washer?

To ensure the durability and smooth operation of a pressure washer:

- Change the oil as per manufacturer’s instructions.

- Clean or replace the air filter to ensure good airflow.

- Inspect and clean the nozzle regularly to prevent clogs.

- Drain the gas tank if you’re storing the washer for a long time.

- Check the hoses for leaks or damage and replace them if needed.

- Follow regular maintenance requirements to keep the washer in optimal condition.

Can I use a pressure washer in cold weather and low water temperature?

You can use a pressure washer in cold weather but it’s more difficult. The water flow rate in the hoses and pump can freeze and damage the equipment. If you plan to use your pressure washer in cold temperatures make sure to winterize it and store it in a warm area when not in use. You can also use anti-freeze solutions for pressure washers.

Some models are designed to use hot water, which can be particularly effective for cleaning in cold weather.

Do I need any accessories?

Common accessories for power washers:

- Different nozzles (0°, 15°, 25°, 40°, and soap nozzle) to adjust spray patterns.

- Extension wands for hard to reach areas.

- Surface cleaners for large flat areas like driveways and decks.

- Hose reels to store hoses neatly and prevent tangling.

- Foam cannon or detergent bottles for soap or cleaning solutions.

- Detergents for cleaning a wide variety of surfaces.